**Planning paragraph structure**

I think five paragraphs would be sufficient, but since we need both an introduction and conclusion, that might add to the total. The user asked for 300-500 characters per paragraph, which means I can aim for 2-6 paragraphs in total, so 5 or 6 sounds good. I'll include key suggestions as a bullet list, making sure they’re separate from the paragraphs but still provide a solid text basis. It’s important to suggest practical implementation methods or tools in a realistic style while using the correct punctuation.**Ensuring formatting consistency**

HTML tags use ASCII, so that’s not an issue. The guideline states, "标点规范,无中英文混用," meaning I shouldn’t mix punctuation. I think this refers to avoiding both Chinese and English punctuation together. I'll use full-width Chinese punctuation like "," and "。" consistently, especially for colons as ":". I must avoid unnecessary blank lines; the HTML should have continuous lines with line breaks, ensuring no consecutive newlines. I'll include one H1 for the document and use H2 and H3 where indicated, focusing on "东莞螺丝机厂家设备选型的五个关键要素."**Organizing key points and suggestions**

I need to cover some critical points for equipment selection. First, I'd outline product and process specifications, like screw size and torque requirements. Then, I would calculate integrated costs considering equipment, tooling, and maintenance. Assessing the manufacturer's engineering and delivery capabilities is next, along with their stability and after-sales service.

I need 3-6 practical suggestions, focusing on methods or tools, like a scoring sheet for equipment evaluation. I’ll ensure I maintain consistent Chinese punctuation throughout and might include casual phrases for relatability. I should check how to format it in HTML properly.**Formatting the content structure**

I think keeping it simple is the way to go. My plan is to include just one `` for the main title "东莞螺丝机厂家设备选型的五个关键要素," followed by an `` for the importance of selection versus price, and a paragraph of 300-500 characters.

Then I’d have an `` for the five key elements, each with an `` and a corresponding paragraph explaining that element and providing suggestions. This sets me up for a total of 6 paragraphs. I made a miscalculation earlier, but six paragraphs around 300 characters each keeps me within the designated word count!**Structuring headings and paragraphs**

I need to create H2 sections for methods and checklists, while unifying them under a logical structure. According to the requirements, I’ll start with an H1 for the title and then manage H2 headings for overall strategy, followed by the five key elements.

My challenge is to summarize everything without exceeding 2000 characters. So, I might aim for 4-5 paragraphs, combining elements where necessary while ensuring each H3 heading is clear. Including a bullet list for practical suggestions is essential too. I’ll keep paragraph lengths around 300-500 characters to meet expectations.**Structuring suggestions and punctuation**

I see that I need to clarify suggestions in a user-friendly format. The requirements specify "提炼3-6条实用、可落地的核心建议/关键要点," which implies a bullet list might be best. I’ll structure an ordered list for the three suggestions beneath the corresponding section without adding new paragraphs.

I’ll also ensure that I use full-width Chinese punctuation throughout, while avoiding any ASCII characters, and take care with the total character count to stay within the specified limits. I'll check everything to finalize the HTML output correctly.

东莞螺丝机厂家设备选型的五个关键要素

前言与整体思路

我在东莞做自动化项目已经十多年了,螺丝机是我踩坑最多的一类设备。刚创业那几年,我总觉得选设备主要看报价和品牌,结果不是节拍达不到,就是良率不稳定,生产一出问题,老板、客户、员工都盯着我,压力特别大。后来慢慢总结出一套选型方法,发现只要前期问题问对了,设备厂家的技术能力和边界看清楚了,后面基本不会被各种小故障牵着鼻子走。说得直白一点,螺丝机选得好不好,直接决定你一条产线能不能睡得踏实,也决定后面要不要被售后电话叫醒。这篇文章我就用创业者的视角,结合在东莞对接过十几家螺丝机厂家的真实经历,把我自己总结的五个关键要素讲清楚,更重要的是给你几套能落地的选型工具,让你在谈方案、砍价格、签合同的时候心里有数,而不是被厂家牵着走。

东莞螺丝机选型的五个关键要素

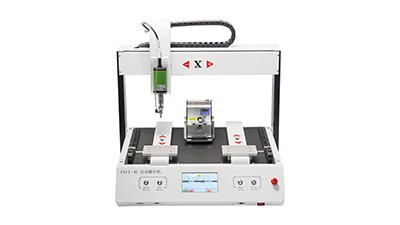

先说这五个关键要素,分别是螺丝锁付工艺和节拍是否匹配、总成本核算是否算全、厂家工程和非标定制能力、设备稳定性和售后体系、以及后续扩展和数据接口预留。,工艺和节拍匹配是底线,你要搞清楚每天产量、班次和休息时间、良率、换线频率,还有螺丝规格、扭力窗口、滑牙和漏锁风险等,否则再贵的设备也可能只是放大的电批。第二,总成本不能只看一台机多少钱,还要把治具、批头等耗材、备件库存、保养人工、停机损失都算进去,有时一台便宜设备一年备件钱就能买半台新的。第三,工程和定制能力决定了厂家的上限,看他能不能根据你的产品做夹具优化、工位布局、程序改动,而不是只会推标准机。第四,稳定性和售后看的是实战,要问清楚他们在东莞和周边有没有常驻工程师、常用备件能不能当天送到、远程协助响应要多久。第五,扩展和数据接口往往被忽略,你更好提前确认能否和现有产线、扫码枪、条码系统、上位机或MES对接,将来要加机械手或者换线,只要做软件参数调整而不是整机推倒重来。

可直接套用的选型建议

建议一:先用节拍测算表把需求算清楚

我现在带团队做任何一条新线,步都是拉着工艺工程师一起做一张节拍测算表,用Excel就能做出来,非常简单但特别有用。表里只放几个关键字段:目标日产量、班次和休息时间、良率预估、单颗螺丝锁付时间、一次装夹需要锁几颗螺丝、换治具和换物料的大致时间。把这些数据填进去,就能倒推一台螺丝机理论上能撑多少产能,需要几工位,要不要做双平台交替工作,也能看出是应该选桌面型独立工位,还是选在线式接主产线的方案。很多老板一上来就问厂家一台机器一小时能锁多少颗螺丝,其实这个数字脱离你自己的工艺场景是没有意义的。你把这张节拍测算表带着去和东莞的螺丝机厂家沟通,让对方按你提供的数据重新核算节拍和工位数,再对比几家给出的参数差异,你会直观感受到谁真正在替你算账,谁只是想把库存机器卖出去,这一步做扎实了,后面选型基本不会跑偏。

建议二:用打分表比较至少三家厂家

第二个我强烈建议用的工具是选型打分表,简单到一页纸就够,但比凭感觉靠谱多了。先列出五个维度:工艺和节拍匹配度、工程和非标改造能力、设备稳定性、售后响应和备件保障、总拥有成本,然后根据你项目的轻重缓急给每个维度打一个权重,比如新产品导入就把工程能力的权重拉高,成熟大批量项目则把稳定性和备件比重拉高。接着,让至少三家东莞本地螺丝机厂家都来现场看线和打样,要求他们给出完整方案和报价,你和团队按照同一套标准一项一项打分,一家厂家可以当场解释自己为什么值得高分,这样大家心里也更坦白。人情面子在选型里很容易干扰判断,用打分的方式把主观感受量化,既能给老板一个清晰的决策依据,也能在后期设备出了问题时回头复盘,看看当初是判断标准本身有问题,还是在执行过程中没有坚守这张打分表。

建议三:通过小批量导入验证稳定性和售后

最后一个非常关键的建议,是一定要给自己留一段小批量导入期,不要一上来就拍板买十几台,哪怕你对这家东莞厂家印象再好也一样。可以先让对方在你现场做一台样机或者短期租赁,在真实生产环境里跑够一个月至少两个完整订单,把不同班次、不同操作员、不同螺丝批次都经历一遍,看工艺节拍是否稳定、锁付良率有没有明显波动、治具是否容易损伤,顺便检验一下售后响应是不是像销售承诺的那样及时。在这个阶段你要刻意去推一下设备的边界,比如临时改工艺、换新物料、模拟简单故障,让工程师现场处理,你就能看出厂家工程能力、程序开放度和备件保障到底怎样。宁可前期慢一点,把工艺节拍、总成本、工程能力、稳定性和扩展接口这五个关键要素都在这一台机器上检验清楚,也比后面整条产线踩坑、返工、停线要划算得多,这一点是我用真金白银换来的经验。

- 使用节拍测算表算清产能和工艺需求,再拿着数据和螺丝机厂家谈方案和报价。

- 用包含五个维度的选型打分表,邀请至少三家厂家同场看线、打样并量化评分后再决策。

- 先做一台样机或短期租赁,通过一个小批量导入周期验证稳定性、良率和售后能力,再批量导入设备。