热门关键词:

` tags, and list items in `

`. I think I can create multiple paragraphs and also include headings. The requirement for tips adds some complexity, especially since each tip needs a paragraph too. However, if I’m not careful, I might exceed the total character limit!**Evaluating paragraph structure** I’m working through the paragraph requirements. If I set up 4 H3 headings with their own paragraphs, that’s 7 total paragraphs. Even at just 300 characters each, I’d exceed the character limit — reaching 2100 characters! So, I really need to minimize the paragraphs somehow. I wonder if I can combine topics within a single paragraph while still using H2/H3 headings. But they want clear headings, so I have to consider that even if it complicates things. Maybe I can follow H3 with list items instead of additional paragraphs? It seems tricky!**Streamlining paragraph structure** I realized there’s flexibility with the H3 headings; they don’t necessarily need separate paragraphs because H3 can be followed by a list. To keep the paragraph count down, I think I can manage with just 3 paragraphs, each around 350 characters, for a total of about 1050 characters. The overall character limit includes the list text too. I’ll need to include at least 3-6 core tips, which can be in list items as short sentences rather than separate paragraphs! That way, I can fit everything within the constraints.**Designing the structure**

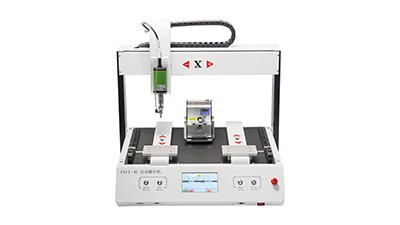

我这几年给不少工厂做自动化改造时发现,自动螺丝机往往被当成一台“能拧螺丝的机器”,但真正在智能制造体系里,它更像是标准化和数据化的入口。过去人工锁付,同一位老师傅上午和下午的扭矩、深度、节拍都可能不一样,工艺实际上是“写在手上”的;上了自动螺丝机之后,扭矩曲线、锁付时间、滑牙重拧次数都能被记录下来,工艺开始变成一套可复现、可追溯的数据模型。说白了,它既是替代人工的一道工序,也是把这道工序纳入数字化闭环的节点。很多企业做智能制造容易一上来就谈大系统、大平台,但我更建议从这类高频、可标准化的工序切入,通过一台螺丝机,把节拍、良率、扭矩窗口这些关键参数“钉死”,你会明显感受到后续良率分析、工时核算、良品追踪都变得有抓手了。

真正决定自动螺丝机成败的,不是机器本身有多高大上,而是“工艺、结构、节拍、人员”四个维度能否一起匹配起来。我踩过的典型坑有几个:一是产品结构没考虑自动锁付空间,结果治具改了三版仍然有螺丝枪伸不进去;二是节拍只算机器理论值,没算上上料、换批、异常处理,最后整线被一台螺丝机卡住;三是质量部门只关心外观和扭矩合格,却没定义清楚哪些数据必须入库、保留多久,导致设备买了带数据接口,却没人真正用。我通常会在项目前期就拉着工艺、结构、质量、设备四方一起做一份“锁付工序清单”,把螺丝规格、预紧要求、允许节拍波动、换型频次、可接受的人工配合程度都写清楚,再决定是选用桌面型、在线型还是多轴平台型螺丝机,这一步做扎实了,后面基本少掉一半返工。

很多工厂上自动螺丝机更大的失败点,是把它当成一笔纯设备采购,而不是一个需要交付结果的项目。我自己的做法是,从一开始就定义三个结果指标:单机实际节拍、首件良率以及一周内异常停机次数,并要求设备商在试产期对这三个指标负责,同时内部指定一位“工序车主”负责对接,把工艺参数、程序版本、治具变更都统一管理。实施过程里,我会强制安排不少于一周的现场试运行,期间让班组长亲自参与调参和换型,使一线人员真正理解这台机器的脾气,而不是只会按启动键。老实讲,前期这几天看起来像是在“浪费产能”,但换来的好处是:后面每次产品变更或换线,你不用再反复请设备商上门,自己团队也能稳住节拍和良率,这对智能制造来说,比多买一两台设备更值。

如果你现在准备在产线上导入自动螺丝机,我比较推荐的个落地方法是“单线小闭环试点法”:先选一条订单稳定、产品结构相对简单的线,只改造其中一到两道螺丝工序,将自动螺丝机与现有工位节拍对齐,再通过简单的数据采集盒把扭矩、节拍和报警信息导入一张可视化看板,不需要一开始就上复杂MES,哪怕用共享表格也行,关键是让一线班组长每天能看到数据变化。第二个实用抓手,是利用现成的锁付数据管理工具或模块化方案,例如市面上一些带扭矩曲线存储和工号绑定功能的控制器,配合条码枪或工位终端,就能实现“哪颗螺丝是谁在什么时间、用什么程序锁的”这种精细追溯。两者结合起来,你既能通过试点验证节拍和良率收益,又能在数据结构上为后续与MES或质量系统对接预留好接口,真正做到从一台螺丝机开始,把智能制造落在看得见、算得清的效益上。

咨询热线

18938263376