**Planning paragraph structure**

I’m thinking we should aim for 4 to 5 paragraphs while ensuring we cover all H2 sections sufficiently. Each H3 would likely need its own paragraph, so ideally, if we want 5 paragraphs, we’ll have 5 H3 titles. They also want 3 to 6 core suggestions, and 5 should work. There's mention of methods or recommended tools that could fit within earlier paragraphs instead of needing their own section. Let’s make sure we describe them inline where appropriate!**Structuring key points**

I'm planning to have 5 H3 sections, each representing a key point. I might include methods or tool details in the last H3, which seems like a good approach. For the overall structure, I think we need 2 major H2 sections, with paragraphs nested under H3s, just as they suggested. The total text should be between 1000 to 2000 characters, and I’ll aim for about 10 sentences in each paragraph while keeping track of the length carefully. I’ll start by drafting the first paragraph from the perspective of a manufacturing veteran.**Planning structure for suggestions**

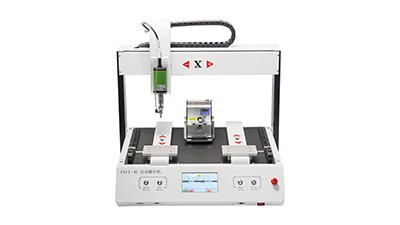

I'm working on structuring my suggestions. The first one is about standardizing and digitalizing process parameters and glue specifications. The second focuses on fixtures and consistency. The third is about data feedback, SPC, and running experiments, starting from a golden sample. The fourth suggestion includes choosing machines with vision alignment for auto dispenser lines in Shenzhen.

I realize I need a fifth suggestion about integration with design for manufacturability. Each suggestion will get its own H3, making for a clean organizational structure with 5 paragraphs under two H2 headings.**Finalizing paragraph structure**

I’m thinking about how to label my points. Calling the first "要点一" and the subsequent ones "要点二、三、四、五" under the second H2 works well. I’ll aim for each paragraph to be between 300 and 500 characters, so I'll target around 360 to 420 characters each. I know counting Chinese characters is tricky, but I’ll estimate based on typical sentence lengths. I’ll begin crafting my first paragraph, aiming for about 9 sentences that average around 35 characters each. Plus, I'll pay attention to the punctuation specifics while writing!**Finalizing HTML structure**

I think it’s a good idea to create an ordered list of suggestion titles before the paragraphs for clarity, but I need to be cautious about whether “每段” refers strictly to paragraph tags. I can include smaller text in list items. The structure will have an introduction under the first H2, followed by a second H2 containing key suggestions in H3 headings. I’ll finalize the HTML layout, ensuring no extra blank lines or incorrect characters. We should maintain the vibe of a seasoned veteran throughout. Let's respond with this HTML!

如何通过深圳自动点胶机提升产品质量与稳定性?

如何通过深圳自动点胶机提升产品质量与稳定性?

整体思路与经验

要点一:先搞清产品与胶,再谈自动点胶

我在深圳做电子制造这些年,看过太多工厂以为买台自动点胶机,良率就能立刻上去,结果发现不过是把原来人工的问题,换成了自动化的大批量放大版。要想真正提升产品质量与稳定性,件事不是选设备,而是把产品结构、胶水特性和质量要求讲清楚。比如焊盘间距多宽、点胶宽度允许波动多少、胶高、固化后的外观标准是什么,能量化的全部写成工艺规范,再配上几套代表性样品,让设备商和工艺、品质站在同一把尺子上沟通。说白了,没有清晰的工艺窗口,任何自动点胶参数都是拍脑袋,设备再贵也只能算是点胶枪,很难真正把质量锁死。

关键要点与落地做法

要点二:用参数和治具锁住工艺窗口

自动点胶要想稳定,关键是把可控的东西全部参数化,并通过治具把不可控的东西尽量消除。我一般会把点胶速度、胶阀开启时间、背压、起收针高度、预热温度这些参数全部整理成表,按不同产品、不同胶水设定标准组合,而且每次调机必须记录变更原因和结果。配合上可靠的工装治具,把产品定位、平面度、间隙先固定住,这样设备就只需要在固定轨迹上重复动作,不用每天跟不同的摆放姿势和基板变形打架。实际落地时,可以做一块经常用来对比的黄金样板,早晚各取几块量胶高和胶宽,只要偏离超过设定区间,就强制停线调整,这比靠师傅肉眼看外观靠谱得多。

要点三:视觉、节拍与环境一起控制

深圳这边节奏快,很多工厂一上来就追节拍,结果点得快是快了,偏移、拉丝、气泡问题却越来越多。我的经验是,自动点胶机至少要配一套靠谱的视觉对位和高度补偿系统,先保证每一下都点在正确的位置和高度上,然后再慢慢提速度。视觉系统不是越花哨越好,而是要识别稳定、调试简单,操作者换班也能快速上手。同时要注意环境和胶水本身的稳定性,车间温湿度、胶桶压力、脱泡时间、开封使用时长都要有明确的控制标准,不然胶水黏度一飘,前面辛辛苦苦调好的参数立刻失效。只盯着机器节拍,不盯这些看似琐碎的小条件,很难真正做到长期稳定生产。

要点四:把数据拉出来,用来“驯服”设备

很多老板问我为什么同样品牌的自动点胶机,别人家越用越稳,自家越用问题越多,其实差别往往就在有没有用数据去驯服设备。最简单的做法,是把点胶相关的关键数据拉出来持续记录,比如每小时不良数、返修主因、抽检到的胶高趋势、设备报警次数和类型,再配一个简单的趋势图和分层统计,每周开一次短会,盯前三大问题往下打。条件允许的话,可以在点胶机上接入简单的数据采集模块,把点胶压力、温度、运行配方直接上传到制造执行系统,出现异常时给出预警,而不是等客户退货才回头查。不要迷信一次性把系统上得多完美,先从三五个最关键的指标做起,数据一稳定,点胶质量自然跟着稳下来。

要点五:从一条试点线开始,配套好软件和培训

说到最后,自动点胶想真正落地,不要一口气全厂铺开,而是先选一条典型产品线做试点,把设备、软件和培训配套跑顺。我一般会用一份很细的导入清单,从样品确认、参数固化、治具验收、点检表编写一直到操作员考核,逐项勾掉,这本身就是一套防呆机制。在软件工具上,我更推荐选用自带视觉教学和配方管理功能的点胶控制系统,操作者只需要按提示拍点、画路径,就能生成程序,同时把参数和批次一起保存,后续换线直接调用,有问题也能快速回溯。培训上不要只讲按钮怎么按,而是让一线人员明白每个参数偏高偏低会出现什么不良,用真实不良样品对比,大家心里有数,设备才不会被当成黑箱去乱调。