**Interpreting paragraph guidelines**

I'm trying to make sense of the requirement that each segment should be 300-500 words. It seems like bullet items might not strictly need to meet that count since they're just segments too. I'll probably ignore keeping them that long unless necessary. However, I should focus on the main narrative paragraphs to meet that 300-500 character guideline. I plan to structure everything in pure HTML, including necessary root tags and keeping it simple but complete. Sounds good!**Structuring the content**

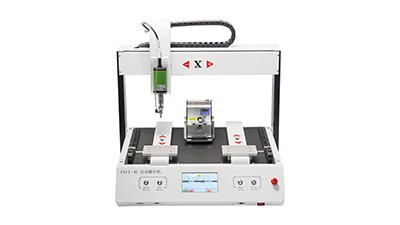

I’m working on the structure of my guide for the automatic screw tightening machine. I’ll start with a main title using `` and follow with multiple `` sections. I’m thinking of including points like typical pitfalls, overall debugging steps, and then 3-6 practical key points as another H2 with H3 for each.

I need to keep it between 1000-2000 characters, aiming for around 1500-1700. Each paragraph should be 300-500 characters, so I need to ensure they have enough content without single-sentence paragraphs. I should also clarify if bullet lists count toward the total paragraph requirement.**Crafting the content in Chinese**

I’m focusing on how to structure my recommendations in Chinese writing. I want to keep each bullet item around 80-150 characters to maintain clarity. I need to offer 3-6 practical key points and maybe list these as an ordered list under an H2 or H3 section. For concrete methods or recommended tools, I’ll suggest a torque testing device and an equipment management spreadsheet.

It's important to use consistent Chinese punctuation and avoid mixing languages in text while keeping certain tool names in uppercase English. I’ll also share my insights as someone who observes the industry closely, highlighting things like data logging and parameter tuning.**Planning the content structure**

I'm structuring my guide for the automatic screw tightening machine in HTML format. It starts with a title and structured sections, including key observation points and detailed debugging steps. Each section has one paragraph, with some understanding that the total character count should stay between 1000-2000.

I need to watch my paragraph lengths, aiming for around 280-320 characters to ensure I don’t exceed the limit. Bullet list items will be shorter, around 40-60 characters each. I'll make sure to focus on using consistent Chinese characters throughout while keeping the HTML tags clear.**Crafting the content properly**

I need to avoid mixing English and Chinese punctuation, like using a period instead of a Chinese full stop. That means I’ll stick to using Chinese punctuation throughout. I'll include tool names without mixed languages and allow some colloquial phrases to make it feel more natural.

I also must maintain structure with H2 and H3 without skipping levels. Each paragraph should consist of about 320-360 characters, focusing on problem areas and key processes. I’ll draft everything in strict HTML format, avoiding excess blank lines for a clean presentation. Time to get started on that content!

自动打螺丝机调试全流程指南,确保高效稳定运行

自动打螺丝机调试全流程指南,确保高效稳定运行

一、先看现场:调试前别急着动参数

这些年跑下来,我越来越确定一个结论:自动打螺丝机出问题,大约有一半根本不是设备本身,而是现场条件和前期规划没想明白。说句实话,我每到一条新产线,件事从来不是打开控制柜,而是先围着工位慢慢看一圈,盯三件事:螺丝本身的品控,产品螺孔的设计和加工精度,治具与操作员的配合节奏。螺丝带不带油,长短是否混料,批次是否稳定,很多企业压根没有检验标准;螺孔有毛刺、攻牙不良,再聪明的设备也只能帮你放大问题。治具如果定位浮动大,工装刚性差,调多少参数都救不回来。因此,我会先让工艺和品质把螺丝和螺孔的标准说清楚,再用最简单的手动电批做几轮试拧,记录扭力感觉和不良类型,哪怕只是粗略分成打滑、浮高、滑牙几类,也能给后面调试提供一个非常现实的边界,不至于一上来就把锅全甩给设备。

二、从硬件到参数:我常用的一套完整调试路径

真正开始调试时,我会坚持一个顺序,从外到内,从硬件到参数,绝不跳步。先看机械部分,依次确认供料轨道是否顺畅,螺丝在气管和锁嘴里有没有明显卡点,批头和螺丝匹配度如何,治具有没有干涉动作,再看整机结构有没有明显振动源,这一步只做慢速点动,不急着打螺丝。第二步是电气与气源检查,看电机和传感器的接线是否可靠,安全回路是否生效,气压是否稳定,有没有一打螺丝压力就掉下去的情况。第三步我会做空载节拍模拟,让设备按预设节拍跑一段时间,只做取放和运动,不上螺丝,用眼睛和耳朵找异常节奏。最后才是正式上螺丝,从单颗试打到多工位连续打,每一个阶段我只允许自己调整少量参数,并用简单表格记录修改前后的结果,哪怕只是记下日期、扭力设置、节拍时间和不良数量,长期看也比凭感觉要稳定得多。

三、我反复验证过的关键要点

很多企业跟我说已经调过很多遍了,但设备还是时好时坏,其实往往是卡在几个细节习惯上。我自己在项目里实践下来,发现只要守住少数几条硬规则,自动打螺丝机的稳定性就会肉眼可见地提升。是调试永远从少量稳定样品开始,先把首件和小批量打扎实,再谈放量,否则前面的小毛病会在规模放大后成倍放大。第二是扭力和打入深度必须数据化,而不是靠感觉说差不多,把不同工位与不同批次产品的样本扭力记录下来,才知道设备的浮动究竟在多少范围之内。第三是每次出现异常停机,只改一类变量,要么改位置,要么改速度,要么改扭力,决不同时动好几处,否则一旦“调好了”,你自己也说不清到底是哪一步生效。最后一点同样重要,就是尽快把调试经验写成简单的文字和图片,让一线操作员看得懂、记得住,否则一换班所有经验重新再来一遍,设备再好也会被折腾出问题。

- 用少量稳定样品做首件确认,首件不合格坚决不放量生产。

- 扭力和打入深度全部记录成数据,定期抽检而不是凭感觉判定。

- 每次排查故障只调整一类参数,保留前后对比记录,方便回退。

- 把调试过程拍照拍视频,写成图文化操作指引交给一线班组。

- 为常见异常建立固定排查顺序,减少来回拆解和无效试错。

四、两套可以直接照搬的落地方法

扭力数据化调试方法

在所有方法里,最见效的一套就是围绕扭力做数据化调试,这套方法我在不同工厂重复用过很多次。具体做法是先确定产品可接受的扭力范围,哪怕一开始只有大致区间,也比完全没有标准强得多,然后在调试阶段固定工位和节拍,每隔几颗就用扭力测试仪抽测一次,连续记录若干结果,标记出更大值、最小值和集中区间。接着对比这些数据与实际不良情况,看是整体偏低导致浮高增多,还是个别异常值对应滑牙或断裂,再有针对性地微调设备扭力上限、下降速度和停留时间。正式量产后,我会要求班组长每天至少抽检几次,并把数据记在一张简单的扭力巡检表上,一旦发现波动超出平时习惯区间,就及时停机排查,而不是等客户投诉。这样做的好处是,把原来很玄乎的“感觉不对”,变成清晰可追踪的扭力曲线,让调试从拍脑袋变成有据可依。

现场管理表和视频复盘的组合用法

第二个我经常推荐的工具组合其实很朴素,就是一张结构清晰的现场记录表配上手机视频复盘。现场记录表里我会固定几栏内容,例如时间、设备编号、当班人员、产品型号、主要参数快照、不良现象和初步原因,每出现一次异常就简要填写,哪怕只写几句关键描述,都比事后“印象里好像”要可靠得多。与此同时,让班组长在出现奇怪故障或频繁卡顿时,用手机从侧面拍下完整打螺丝过程,注意把供料、运动轨迹、治具状态和操作员动作都收入画面,后面和设备工程师一起对照记录表复盘,经常能发现当时没人注意到的小细节,比如某个动作稍微提前了一点,或者某个工位的产品摆放角度总是偏了一点。通过这种表格加视频的组合,每次调试结束都能留下清晰的“病例档案”,下次遇到类似问题只要对照过往案例,很快就能锁定范围,大幅减少靠经验瞎猜的时间。

五、让设备长期稳定的最后几步

从行业观察者的角度看,一台自动打螺丝机能不能长期稳定运行,关键不在次调得有多漂亮,而在有没有把那次成功变成可以复制的日常机制。我的做法是,在完成初次量产验证后,一定拉上工艺、品质和生产几方,开一个节奏很快的小复盘会,明确记录下本次调试的关键参数、典型问题和处理顺序,并同步更新到现场的标准作业书里。接着,为设备设置一个简单的预防性保养计划,例如固定时间清理锁嘴和供料轨道,检查批头磨损,更换易损件,用表单勾选确认,避免拖到设备明显异常才想起维护。最后,还要允许设备在受控范围内持续优化,比如每隔一段时间根据数据适度缩短节拍,但每次调整都必须可追溯,能随时回到一个曾经验证过稳定的参数版本。只有这样,自动打螺丝机才不是某个工程师个人技能的延伸,而是变成一套团队都能理解和维护的稳定生产能力。