**Structuring the content**

I’m planning to create 3-6 key points for this piece. I might set up 4 sections; 3 will cover pain points and 1 will focus on implementation methods. Each section needs to be around 300-500 characters, targeting about 350-400 characters per paragraph. I'm considering a clear heading structure: one main title (h1), several h2s for sections, and h3s for the specific points. This keeps everything organized and easy to read, ensuring we cover the necessary details effectively.**Determining paragraph structure**

I'm thinking about the content layout. Ideally, we want around 6 paragraphs, each 300-500 characters, totaling 1800-3000 characters, but the requirement is for 1000-2000 characters. So, 6 paragraphs would work, but maybe 5 is simpler — that gives around 1500 characters. I’ll structure it with 3 h3s under the first h2 and 2 h3s under the second. The h3s can represent key points, and I could also include a summary list of 3-6 practical suggestions at the end.**Refining the structure**

They’d like a clearer structure, so I'm thinking of organizing it like this: starting with a main title (h1) and then moving into specific sections. The second section will cover industry pain points I see in factories, providing around 300-500 characters. The next h2 will highlight the key problems that a fully automatic screw machine can solve. I'll introduce a section for core suggestions with a list of 3-6 key points. Finally, I’ll detail implementation steps, including specific tools and methods, adding two new h3s for clarity. This keeps everything neat and focused!**Designing content layout**

I’m aiming for 5 paragraphs, each around 300-350 characters, totaling 1500-1750 characters. They want detailed points, so I’ll include at least one h3 under each h2. Here’s what I’m thinking: The first h2 will cover industry pain points I've observed on the production floor, with an h3 discussing why manual screw tightening has become a bottleneck. The second h2 will explain how fully automatic screw machines address core issues with an h3 highlighting improvements in efficiency and costs. In the third section, I’ll give practical advice, summarizing key points in an ordered list. Finally, the last h2 will focus on low-risk implementation strategies and include some useful tools while maintaining a clean layout without extra spaces.**Creating final content**

I need to ensure that the content provides unique insights and practical solutions to meet the user's needs. I’ll include 1-2 implementation methods or recommended tools in the last paragraph. I plan to clearly mention "方法一" and "方法二." I'll recommend tools like a torque controller with curve recording and barcode traceability, as well as a lightweight data dashboard or shop floor execution system. Plus, I’ll make sure that the topic "全自动打螺丝机能解决哪些行业痛点?" is well addressed without being too generic, while incorporating specific details. Time to finalize the HTML!

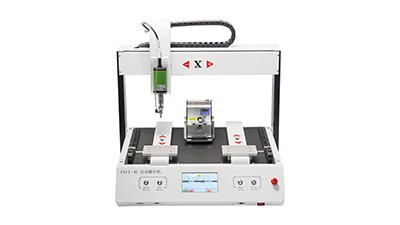

全自动打螺丝机能解决哪些行业痛点?

行业痛点:我在生产现场看到的真问题

人工打螺丝的隐性成本

我这几年跑下来,发现很多做消费电子、小家电、汽车零部件的工厂,看起来自动化程度不低,但一到装配末端,螺丝工位还是一排人拿着电批埋头苦干。人工打螺丝的痛点很集中:节拍不稳定,同一条线早晚班节拍能差二十个百分点;扭矩全靠手感,返工和内部不良率居高不下;人一累就容易滑牙、漏打、错打型号,现场还要安排班组长专门巡查。说白了,螺丝工位往往成了整条线的短板,一旦人手紧张或者新人比例高,产能计划和交期承诺就完全没法心里有数。同时,手工作业对工伤、噪音、粉尘暴露的风险也更高,年轻工人越来越不愿意长期干这类又累又枯燥的岗位,企业的人力成本、培训成本和离职替补成本被一步步推高,账面上看是几名操作工,实质上拖累的是整条产线的稳定性和组织效率。

自动化设备带来的核心价值

从“少人”到“控质量、稳节拍”

从企业运营角度看,全自动打螺丝机解决的绝不只是“少几个人”的问题,而是把一个高度依赖个人经验的黑箱工序,变成可度量、可追溯的标准化工艺。设备可以按扭矩、角度、时间控制,每颗螺丝的锁付数据都能被记录下来,用于客诉追查和工艺优化,良率往往可以抬高一个档位。更重要的是,节拍变得可预测,哪些工位是瓶颈、每天理论产能是多少,管理层可以算得更清楚,排产和接单就更敢放量。很多工厂在导入后发现,同样场地下产出多了百分之十到百分之三十,但人员结构更扁平,班组长不再围着现场救火,而是有精力做培训和持续改善。这种从“人盯人”到“用数据控过程”的转变,也让企业在面对客户审核、体系认证时更有底气,长期看相当于给工厂的竞争力加了一道“看不见的护城河”。

给管理层的关键决策要点

三到五条最值得优先落地的建议

站在顾问视角,如果企业想借全自动打螺丝机真正解决痛点,而不是买几台设备摆在那儿,至少要想清楚几件事:,要把它当成工艺升级项目,而不是简单的“换设备”,事前完成工位节拍测量、螺丝规格梳理、扭矩窗口验证,把基础数据打牢;第二,要优先改造最影响交期、返工最多的那几个工位,哪怕只上两三台设备,也要让业务和老板看到明显的节拍改善和良率提升;第三,要同步设计好治具、防错、扭矩管理和点检制度,让人机协同,而不是指望机器一个人扛所有责任;第四,要提前评估维保能力和备件策略,避免后期因为小故障频繁停线。下面我把这些思路提炼成几条更容易落地的关键要点,方便你直接带回去和团队讨论与决策。

- 导入前先做一周左右的节拍与不良数据诊断,找出螺丝相关的真瓶颈工位,再决定设备型号和数量。

- 优先锁定三到五个高频、生命周期长的产品或机型导入,避免到处少量铺开导致调试复杂、维保压力大。

- 在方案评审阶段就把工艺、品保、设备、生产四个角色拉在一起,统一扭矩标准、验收指标和数据留存要求。

- 治具设计时优先考虑换型速度和通用性,预留后续产品迭代的空间,减少以后每改一次产品就大动干戈的情况。

- 导入初期设置一段人工与自动工位共存期,一方面作为应急和对标,另一方面用实测数据消除一线员工的抵触情绪。

如何低风险落地全自动打螺丝机

试点路径与推荐工具

在落地路径上,我更推荐“先试点、再复制”的策略,而不是一口气把整条线推倒重来。方法一是选一条典型产线、一个产品族,先在最稳定、螺丝规格相对集中的工位上导入全自动打螺丝机,配套做导入前后节拍、良率、人员配置的对比,用一个完整的高峰和低峰周期来验证投资回报,再决定是否放大投入。方法二是引入简单易用的数据工具,把设备能力真正变成管理能力,比如选用带扭矩曲线记录和条码追溯功能的电批控制器,加上一套轻量级的数据看板或车间执行系统,让每颗螺丝的合格率、节拍波动直接挂到班组屏幕上。坦白讲,哪怕先从一台小设备加一块廉价屏幕做起来,只要指标透明、责任清晰,团队很快就能感受到自动化带来的安全感和掌控感,后续再按同一标准去复制到多条线、多工厂,就会顺畅得多。