**Following HTML requirements**

I need to make sure that each paragraph in my HTML has between 300-500 characters, so I’ll keep that in mind while writing. While a few shorter paragraphs might be acceptable, they’re pushing for compliance. I understand they want pure HTML with no markdown or extra line breaks, so I'll keep it concise and inline. I'll stick to using Chinese punctuation and avoid mixing with English, opting for "行不行" instead of "OK".**Structuring the HTML content**

I need to create 3-6 key advice points, each under an H3 tag, followed by a paragraph and maybe a list. While they haven't forbidden HTML and head tags, I’m preparing a full article format. I’ll design the content while keeping track of character counts. A Chinese sentence averages about 15-20 characters, which means I can target 8-10 sentences per paragraph to reach around 350 characters. I’ll need multiple paragraphs, aiming for a total of about 1500 characters, but each must still be at least 300.**Planning paragraph structure**

I’m thinking about structuring my content with 4-5 paragraphs. The intro would be an H2 with one paragraph, then the second H2 could have 5 H3 sub-sections, each with a paragraph. That gives us a total of 6 paragraphs, roughly around 1800 characters if I keep each at around 300. I need to ensure I stay under 2000 characters, so targeting around 310 per paragraph sounds acceptable.

To avoid exceeding limits, I might only include two H2 sections instead of three while still following the requirement for H2s in key segments.**Counting paragraphs for structure**

Alright, let me break down the total paragraph count. I have H2-1 with 1 paragraph, H2-2 containing 5 H3 sub-sections, each with a paragraph, making it 1 + 5 + 1 = 7 or 8 paragraphs. If I aim for 300 characters each, that pushes the total over 2000. They specified paragraphs should be 300-500, but I want to stay compliant.

I could combine H3 points to reduce the number, perhaps to 3 under the second H2, which would give me a total of 5 paragraphs. Each would then be around 320 characters, which I'm thinking could work well, especially if I include some lists after the method descriptions.**Evaluating Wikipedia accuracy**

I’m thinking about how reliable Wikipedia is for research. It’s known for being editable by users, which can lead to inaccuracies. I should consider both the pros and cons.

On one hand, it’s frequently updated with a plethora of information which is quite convenient. On the other hand, there’s a risk of encountering misinformation since anyone can edit entries. I wonder about the importance of verifying any controversial or complex topics using primary sources or peer-reviewed articles.

There's also the different treatment of articles: popular topics might have stricter editorial controls while niche subjects may not. I think there's no one-size-fits-all answer. It's essential to assess each article's edit history and use critical thinking when evaluating the content.

In summary, Wikipedia can be a good starting point for research, but I shouldn’t rely solely on it without verification from more authoritative sources. It’s about balance!

如何选择适合自己的深圳自动点胶机设备

如何选择适合自己的深圳自动点胶机设备

先想清楚自己要什么

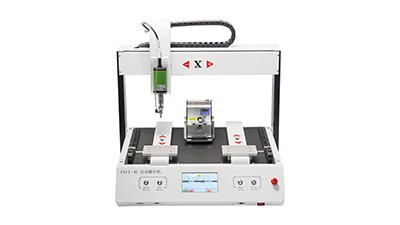

在深圳做自动点胶设备这行,我已经折腾了十来年,看过太多企业选设备只看价格或者听销售一嘴好话,结果不是产能上不去,就是良率一直提不高。点胶机说白了就是帮你稳定、快速、可控地把胶放到该去的地方,但每家工艺、节拍、人员情况都不一样,所以“适合自己”不是一句空话。我自己给客户选型,步一定是把产品结构、胶水类型、日出货量、现有问题一条条问清楚,再回头看有没有必要上三轴平台、在线点胶、视觉对位这些配置。你现在要做的,不是先问哪家设备便宜,而是先搞明白:你希望通过这台点胶机解决哪两三件最要命的事,是人手不够、效率太低,还是良率不稳定、返修成本太高,只要目标清晰,后面所有选型就有了标尺。这一步很多老板嫌麻烦,但真的是关键中的关键。

选型时我坚持的三条硬标准

一、产能和良率优先于参数

条,我自己最看重的是产能节拍和良率,而不是设备参数表上那些看起来很炫的数字。你要先算一笔最朴素的账:一台机每天要工作多少小时,每小时要完成多少件,每件允许的点胶时间是多少秒,再反推需要多快的移动速度、多高的自动化程度。深圳这边做标配台式点胶机的厂家很多,有的为了报价好看,把更大速度写得很漂亮,但真上胶之后因为加速度不稳、治具刚性差,只能慢慢跑,这种设备买回去等于占地方。我一般会要求对方按我真实产品做一次完整节拍测试,更好让操作员在旁边一起看,时间、良率、操作动作都记录下来,看的是整体产出,而不是演示时那几秒的峰值速度。如果这一步都没有数据支撑,只听厂家保证“肯定没问题”,那基本就是在赌运气。

二、先搞懂胶水工艺再看机器

第二条,一定要盯死“胶水加工艺”这件事,而不是单纯买一台机器回来自己摸索。不同的胶水有不同的粘度、起始固化时间、对温度湿度的敏感程度,同样一套点胶头和供胶系统,用在低粘度流动性很好的胶上没问题,换成高粘度的导热胶就容易拉丝、断胶,最后只能靠工人不停擦。深圳有些厂家会直接告诉你“什么胶都能打”,听着很爽,但真正负责的,是愿意提前拿你的胶水和样品板,在自家工艺室做多轮试样,把针头规格、气压、时间、轨迹、预热这些参数都摸透,然后把打样视频、参数表一并给你,对应不同批次胶水怎么微调也写清楚。以后你工艺有小改动,只要按这个思路调整,多数问题自己就能搞定,不会每次都被设备商牵着鼻子走。这一块搞明白,比多花一点钱上所谓高端配置要划算得多。

三、维护成本和售后响应要算进去

第三条,别忽视维护成本和售后响应,这个在深圳尤其明显,同样一台点胶机,有的客户用了三年还在稳稳跑,有的半年轴就开始抖,大部分区别不在于一两根丝杆,而在于整体设计和日常维护是否容易执行。我自己选设备时,会优先看结构是不是简单易懂,易损件更换位置是不是顺手,常用参数有没有分级权限,现场班长能不能在不找工程师的情况下处理八成的小问题。其次就是问清楚备件价格、保养周期、上门响应时间,更好让对方把实际服务案例摊在桌上看,包括高峰期是不是会排队。如果厂家连一套基础保养手册、常见故障对照表都拿不出来,只是在那边拍胸脯保证“有事随时找我”,那多半说明体系还不成熟,出了问题你会非常被动。设备再便宜,停线的损失也足够把价差吃掉。

两个能直接拿去用的落地方法

说到真正落地,我这几年总结了两个简单又好用的方法,只要愿意花一两天时间,基本能把大部分深圳点胶机厂家筛一遍。个方法是“打样加对比表”,先把自己主力产品挑三五款出来,明确胶水、点胶要求、节拍目标,发给三家左右你觉得靠谱的厂家,请他们在同一条件下打样并录视频,然后你用一张电子表格,把外观效果、节拍数据、操作难度、噪音、维护便利这些维度按一到五分打分,现场看机的时候再把自己的真实感受补进去。第二个方法是“试产一周”,正式下大单前,先租一台或要求对方提供样机,放到你现有产线跑一周真实订单,把停机原因、换线时间、操作员反馈全部记录下来,周会时拉上工艺、质量、生产一起评估,这样选出来的设备,基本不会偏差太离谱。

- 打样加对比表:同款产品让不同厂家在同一条件下打样,用电子表格把外观、节拍、操作感受逐项打分,对比时就不会被一两句好听话带偏。

- 试产一周:把样机拉到真实产线跑一周订单,记录停机和问题点,让工艺、质量、生产一起评估,用数据和现场体验来决定买不买。